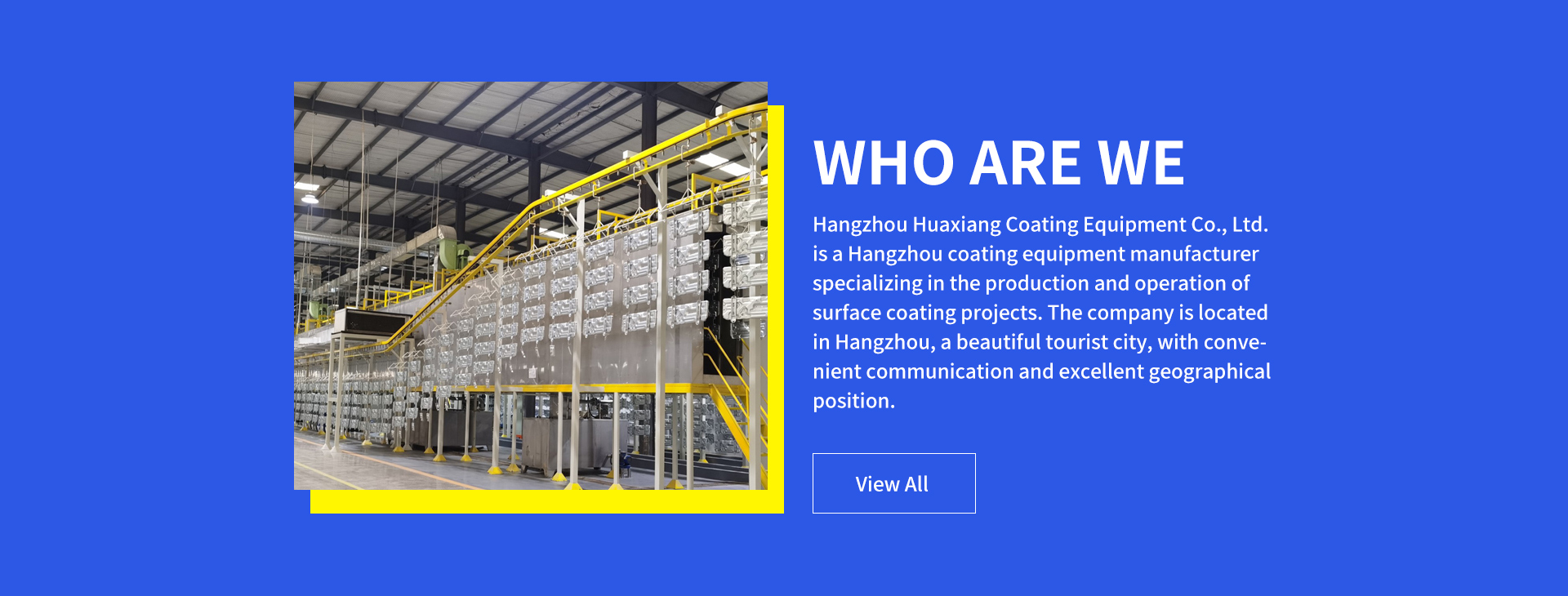

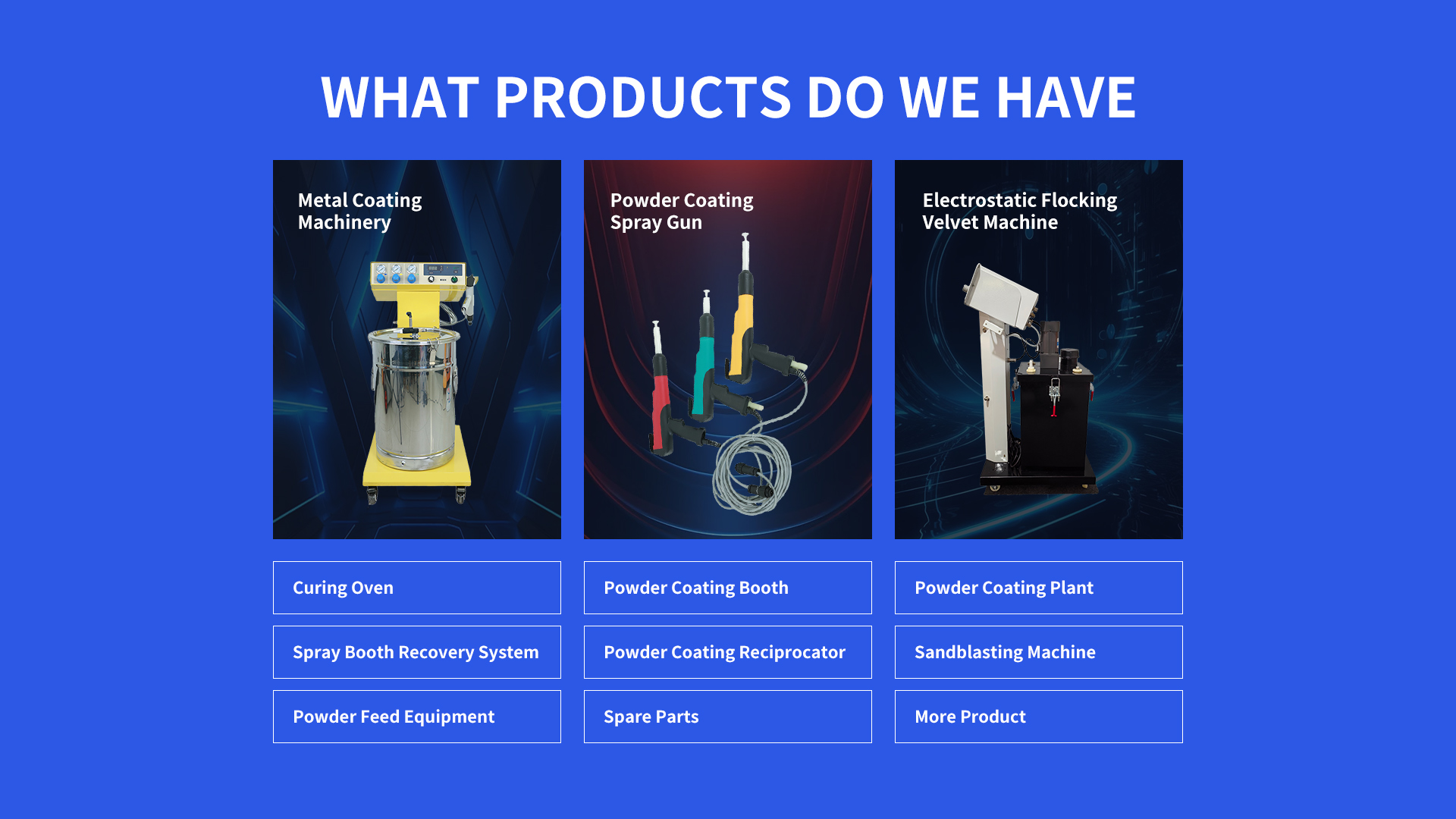

1. Powder Coat Machine for Sale Overview and Components

A Powder Coat Machine for Sale automates the application of dry, electrostatic powder to metal surfaces, cured into a durable finish. Core components include a high-voltage spray gun, powder feeder, conveyor system, curing oven, and control unit. Advanced models feature robotic arms for precision, IoT sensors for real-time adjustments, and modular designs for scalability.

2. Applications of Powder Coat Machines Available for Purchase

These machines are ideal for automotive (wheels, engine parts), aerospace (aircraft components), furniture (metal frames), and consumer electronics (appliance housings). They deliver uniform, corrosion-resistant coatings on complex geometries, making them essential for industries prioritizing quality and efficiency.

3. Pricing of Powder Coat Machines for Sale

Prices range from 10,000formanualbenchtopunitsto300,000+ for fully automated production lines. Entry-level systems suit small workshops, while robotic models with multi-axis sprayers cater to large factories. Additional costs include maintenance, powder materials, and energy consumption.

4. How to Operate a Powder Coat Machine Correctly

Pre-treat surfaces via sandblasting or chemical cleaning to ensure adhesion. Set the electrostatic gun to 50–90 kV for optimal powder charging. Adjust conveyor speed (1–5 m/min) to control coating thickness. Cure parts at 160–200°C for 10–20 minutes. Clean filters and nozzles after each use to prevent clogs.

5. Tips for Choosing the Right Powder Coat Machine for Sale

Assess production volume, part size, and coating type. For high-throughput needs, prioritize robotic systems with programmable spray patterns. Check certifications (CE, UL) and energy efficiency ratings. Verify warranty terms, technical support, and availability of spare parts.

6. Safety Precautions When Using Powder Coating Equipment

Install explosion-proof ventilation to manage combustible dust. Operators must wear NIOSH-approved respirators, gloves, and anti-static clothing. Ground all equipment to prevent electrostatic discharge. Regularly inspect electrical systems and emergency stop functions.

7. Why Invest in a Modern Powder Coat Machine for Sale

Automation reduces material waste by up to 50%, lowering operational costs. Precision robotics ensure 98% coating consistency, critical for industries like medical devices. Energy-efficient ovens with heat recovery cut power use by 25%, aligning with sustainability goals.

8. FAQs About Powder Coat Machines for Sale

Q: What industries benefit most from powder coat machines?

A: Automotive and aerospace sectors achieve high-quality finishes at scale.

Q: How to maintain a powder coating machine?

A: Clean spray guns daily and inspect ovens monthly for temperature accuracy.

Q: Can these machines coat small batches?

A: Yes, programmable settings optimize efficiency for limited runs.

Q: Are eco-friendly powder options available?

A: Yes, VOC-free powders meet environmental regulations.

Q: What is the average ROI timeline?

A: Most businesses recoup costs in 12–24 months via reduced waste and labor.

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com